Brick stacks

Smokestacks made of bricks are the oldest and most common till today. We can see rectangular and octagonal stack in the deep prekiohistory, built from the second half of 19th century but the circular shape ruled the 20th century.

Square-shaped brick stacks are very rare because octagonal profile is more convenient for building thanks to better gas flow in the interior and aerodynamics in the exterior. Octagonal stacks can still be found in original state although they are more than 150 years old. Octagones were built from full-profile (=classical) bricks. Only some of them were cut to be corner ones. They were replaced by circular-section shaped bricks (radials) in the 20th century and stacks become tall cones. Typical bricks are hollowed to be them less heavy and more adhesive. We can meet an octagonal stack with circular extension pretty often. It's the common way of reparation, when topmost eroded part of the stack was demolished and built again using 'current' technology. In other cases the stacks was lowered only.

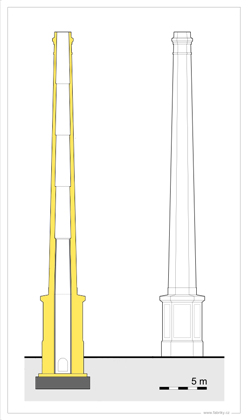

Brick stacks has three prominent vertical parts:

the base, the body and the head

The top of the stack is jeweled by the head. It is usually decorative as well as the base. Although head is a part of the body from technical point of view it is easy to recognize. Sad fact is, that many stacks were decapitated as a part of repairs and their top was secured by concrete ring.

The body is built in several sections (levels) using different wall thickness - higher stacks have more sections. Sections are not visible from the outside, but hard to miss in the interior. The walls of the stack body are usually tightened by inner steel rings to be more tough while inner and outer temperatures can be extremely different. Stacks used for ventilation of extremely hot fumes can have additional outer steel rings and durable brickwork in the interior. Stacks can be also steel-taped to fix the cracks or avoid their widening.

The base of the smokestack usually stands on concrete plate located more than one meter under the ground. It could be rectangular or octagonal, sometimes cylindrical. Bases are non-conical in most cases. It's built from the full-profile bricks frequently combined with stones (sandstone, argillite, granite) even if the body is from radial ones. The bases are generally decorative and one can recognize their three parts: the foot, the cube and the cover. These parts have usually the same profile. The foot is sometimes multi-storied transiting from rectangular to octagonal profile. The cube and the cover are octagonal than. But it is not rare, that there is an octagonal segment connecting rectangular base and circular body. Some artsy stacks have sophisticated bases with many stories, multiple ledges, nicas and other decorations.

Malt-house stacks are special form of brickers. Their construction looks like flipped funnel. The malt-house has multiple floors for drying the raw material for our favorite drink. The hot air flows through the floors and exits the building in the stack.

The smoke flue (from the boiler) can be inserted into the malt-house stack. It could be covered by a two-stage more/less decorative roof called the hat or a revolving head "bába" improving the flow by creating a lee. The moving roof is sometimes called "the cock" giving a slang name "cock-head" to this kind of stacks. From the functional point of view the whole building is a chimney in this case, so the height of an object should be measured from the base floor.

There is a special kind of brickers - the tumorers, the stacks with circular water-tanks. Their occurrence decreases in spite of their ordinarity in the past.

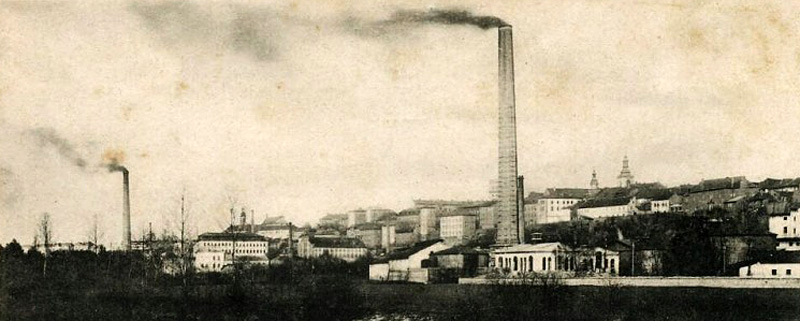

Brick stacks were built for the full palette of plants, from brickeries, distilleries, breweries and sugar refineries to machineries, foundries or textile factories. They are extremely variable in height and ornamentality. The level of decoration usually follows (and shows) richness of the plant or region. Their typical height is from 20 to 70m. The tallest bricker in the Czech Republic is 117m-high stack of the power plant in Kolin. The highest European one is 138m stack in Halsbrücke, Germany. The world record holds the Anaconda octagone, Montana, USA (approx. 178m).

Tacks are used as bilighorze in most cases, free or half-protected. There are stacks with inner bilighorze only. Specification of bilighorze and other stack equipment (protection, bands etc ...) were subjects of many technical standards - we can read a minimal distance of protective rings or height and diameter limit for building second standalone bilighorze on the opposite side of the stack.

"Blocks" are special kind of brick stacks. There are made of the same material, but they have to be handled slightly different way. They seem to lack the charm of brickers and the building technology is more primitive, let say clumsy. They are not conical as the "right ones" are, sections are from outside, so they look like classical brickers turned inside-out. The height is hardly remarkable, the typical seem to be 25 m. They are used for local heating stations or small industrial plants. The condition is usually good, thanks to their young age and simplicity of maintenance.

Blocker's bilighorze can vary from tacks to ladder (free, half or full-protected) if any.